Product Innovation

Connecting our shoe-making heritage to a more circular future.

Innovation and craftsmanship have been at the heart of our brand for over 45 years. From the outset, Camper was founded on the principles of sustainable living, and our first-ever shoe, Camaleon, was crafted out of recycled rubber tires and leather offcuts. Today, we still use recycled materials to make desirable products. Our young designers work with seasoned artisans and technicians to develop and implement new techniques for a more sustainable future. Creating long-lasting products to eliminate waste is integral to our ethos. And although there is no one single solution to becoming circular, we are constantly striving to find and use better materials, better energy sources, and a more simplistic means of production to become a more responsible company.

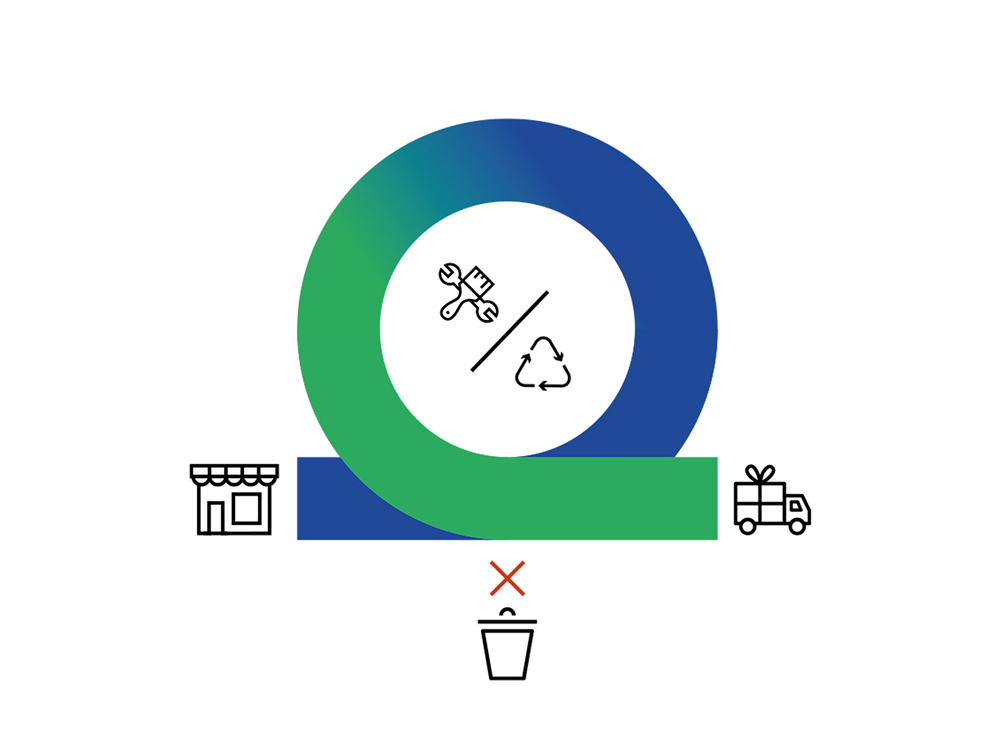

In our quest for true sustainability, we are pushing towards circularity, a process in which raw materials, components, and products are recycled rather than wasted. As recommended by the Ellen McArthur Foundation, we aim to transition to a more circular economy, a new economic system, which uses renewable energy and more natural materials to reap better results for our community and our planet. Therefore, our business model, materials, and production processes are shifting towards a better, kinder future where everything is valued and nothing is wasted.

How are we becoming more circular as a brand?

As shoemakers with an environmental conscience, we are committed to designing and producing durable, long-lasting products that never reach a landfill, unlike the million tonnes of shoes, clothing, and textiles that do. We are working towards circularity in many ways, but above all, product innovation and design are the keys to minimizing waste during production. By starting with a considered, more circular design process, we use better materials to make longer-lasting products that can be disassembled, reused, and repurposed at the end of their lives. Maximum wear, minimal waste.

Circularity begins with the selection of better materials to produce long-lasting, quality products. We are committed to using more ethically sourced, natural materials, including leather certified by the Leather Working Group, recycled materials approved by the Global Recycled Standard, and cotton recognized by the Better Cotton Initiative.

We are incorporating more innovative materials like TENCEL™ Lyocell that is circular by the nature of its production, originating from renewable raw wood pulp. We are crafting better outsoles using bio-based sugarcane, a natural plant-based material from a fully renewable, fast-growing resource. Other biodegradable innovations include recycled hemp that uses 93% less water than traditional cotton, and HyphaLite, a 100% natural fiber derived from mushrooms.

Shoes are complex to produce, often involving many different components. By using fewer parts, we can minimize waste and consume less energy by shortening the production time. We are constantly looking for ways to reduce our waste and energy consumption by designing with minimal elements and simplified production techniques.

Our iconic Wabi is a prime example of an environmentally conscious shoe with a minimalist approach. Launched over twenty years ago, our original Wabi was a pioneer of waste reduction crafted from a single piece of material. Other lines in our collections are designed and produced using mono materials, a technique that creates footwear uppers directly from the yarn rather than from fabric, so there are no offcuts. As this shoemaking method has fewer steps in the manufacturing process, this is a significant step towards reducing energy consumption.

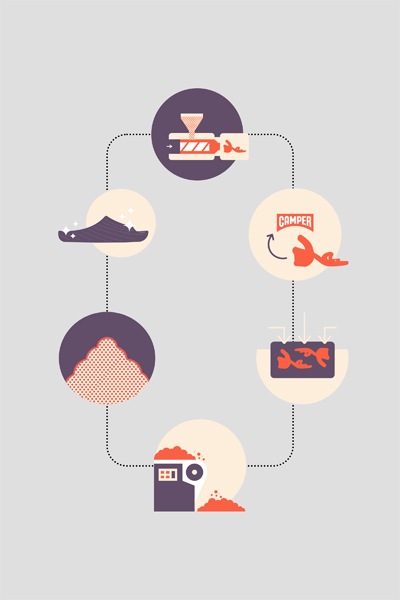

We understand that embracing recycled materials is no longer enough. To be truly circular, a shoe must also be recyclable into a new one. Although there is a high level of complexity to designing fully circular footwear, we continue to innovate.

Our Kobarah and Wabi sandal are specifically designed to be circular. At the end of their lives, they can be disassembled and crafted into new shoes. Nothing is wasted during their life cycle.

For us, the durability and longevity of our products are part of our contribution to sustainable development. We want to make shoes that last forever because we do not want them to be destined for landfills. This is why we select the most durable materials and favor designs with a timeless aesthetic. To further prove our commitment to durability, we offer a repair service at selected stores and a lifetime guarantee with every pair of our iconic Pelotas Ariel. Since durability is at the core of every product that we produce, our technicians are continually testing the performance of our footwear. We also select premium partners like Vibram and Michelin to create technically outstanding shoes.